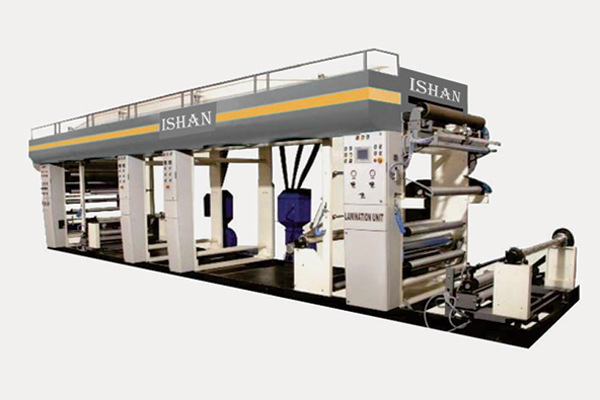

We are leading and most prominent Exporter of Lamination Machine in India. Ishan Internationals is the trade name that counts for the finest deals in the lamination machine for laminator’s wholesale market. We are offering our esteem customers with the finest quality range of lamination machines which are ideal to laminate identity cards, pan cards, documents etc. Our customers can avail from us the best range of Lamination machine that are dimensionally accurate and corrosion resistant.

All our machines are made-up with the aid of avant-garde technology and using supreme grade raw material which is picked up from specialized suppliers of the industry. Our accessible machines are developed in tune with set industry standards and are available in industrial market with numerous technical provisions. The offered lamination machine is use for laminating various items. Our lamination machine is provided in modified according to the information detailed by our highly regarded customers. Provided lamination machine is checked in terms of quality for delivering a quality range to customers.

| MODELS | ISLL 1000MM | ISLL 1300MM | |||

| Working Web Width* | 1000 mm | 1300 mm | |||

| Max machine speed | Up to 300 mtrs/min | ||||

| Un-winder / Re-winder diameter | 800mm (350 kgs.) to 1000mm (500 kgs.) | ||||

Laminates Substrates Material : Polyester, BOPP, LDPE, Aluminum Foil etc

* Can bevary as per requirement, if possible

| MODELS | ISBL 1000MM | ISBL 1300MM |

| Working Web Width* | 1000 mm | 1300 mm |

| Max machine speed | Up to 150 mtrs/min | |

Material : Polyster, Poly, BOPP etc

* Can be vary as per requirement, if possible

** Depending on the film quality, thickness and ink quality and ink coverage.

Suitable for manufacture of all kind of bags viz T-Shirt Bags, D-Punch Bags, Grocery Bags etc.

@2024 Ishan International All Rights Reserved.

Powered by : #1 Vinayak InfoSoft – SEO Company Ahmedabad